Paint production¶

The problem description in this section is taken from Section 7.5 Paint production of the book Applications of optimization with Xpress-MP. As a part of its weekly production a paint company produces five batches of paints, always the same, for some big clients who have a stable demand. Every paint batch is produced in a single production process, all in the same blender that needs to be cleaned between every two batches. The durations of blending paint batches 1 to 5 are respectively 40, 35, 45, 32, and 50 minutes. The cleaning times depend on the colors and the paint types. For example, a long cleaning period is required if an oil-based paint is produced after a water-based paint, or to produce white paint after a dark color. The times are given in minutes in the following table:

CLEAN(i,j) |

1 |

2 |

3 |

4 |

5 |

1 |

0 |

11 |

7 |

13 |

11 |

2 |

5 |

0 |

13 |

15 |

15 |

3 |

13 |

15 |

0 |

23 |

11 |

4 |

9 |

13 |

5 |

0 |

3 |

5 |

3 |

7 |

7 |

7 |

0 |

Since the company also has other activities, it wishes to deal with this weekly production in the shortest possible time (blending and cleaning). Which is the corresponding order of paint batches? The order will be applied every week, so the cleaning time between the last batch of one week and the first of the following week needs to be counted for the total duration of cleaning.

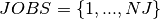

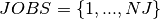

Formulation of model 1¶

As for the problem in section 11.3 we are going to present two alternative model formulations. The first one is closer to the Mathematical Programming formulation in Applications of optimization with Xpress-MP, the second uses a two-dimensional element constraint. Let  be the set of batches to produce,

be the set of batches to produce,  the processing time for batch

the processing time for batch  , and

, and  the cleaning time between the consecutive batches

the cleaning time between the consecutive batches  and

and  . We introduce decision variables

. We introduce decision variables  taking their values in

taking their values in  , to indicate the successor of every job, and variables

, to indicate the successor of every job, and variables  for the duration of the cleaning after every job. The cleaning time after every job is obtained by indexing

for the duration of the cleaning after every job. The cleaning time after every job is obtained by indexing  with the value of

with the value of  . We thus have the following problem formulation:

. We thus have the following problem formulation:

The objective function sums up the processing and cleaning times of all batches. The last (all-different) constraint guarantees that every batch occurs exactly once in the production sequence.

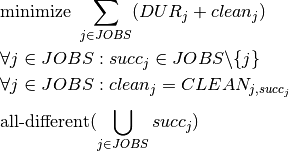

Unfortunately, this model does not guarantee that the solution forms a single cycle. Solving it indeed results in a total duration of 239 with an invalid solution that contains two sub-cycles 1  3

3  2

2  1 and 4

1 and 4  5

5  4. A first possibility is to add a disjunction excluding this solution to our model and re-solve it iteratively until we reach a solution without sub-cycles.

4. A first possibility is to add a disjunction excluding this solution to our model and re-solve it iteratively until we reach a solution without sub-cycles.

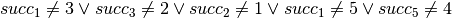

However, this procedure is likely to become impractical with larger data sets since it may potentially introduce an extremely large number of disjunctions. We therefore choose a different, a-priori formulation of the sub-cycle elimination constraints with a variable  per batch and

per batch and  implication constraints.

implication constraints.

The variables  correspond to the position of job

correspond to the position of job  in the production cycle. With these constraints, job 1 always takes the first position.

in the production cycle. With these constraints, job 1 always takes the first position.

Implementation of model 1¶

The implementation of the model formulated in the previous section is quite straightforward. The sub-cycle elimination constraints are implemented as logic relations with implies (a stronger formulation of these constraints is obtained by replacing the implications by equivalences, using KEquiv).

// Number of paint batches (=jobs)

int NJ = 5;

// Durations of jobs

int DUR[] = {40, 35, 45, 32, 50};

// Cleaning times between jobs

int CLEAN[5][5] = {

{ 0, 11, 7, 13, 11 },

{ 5, 0, 13, 15, 15 },

{ 13, 15, 0, 23, 11 },

{ 9, 13, 5, 0, 3 },

{ 3, 7, 7, 7, 0 } };

// Cleaning times after a batch

KIntArray CB;

// Successor of a batch

KIntVarArray succ;

// Cleaning time after batches

KIntVarArray clean;

// Variables for excluding subtours

KIntVarArray y;

// Objective variable

KIntVar * cycleTime;

// Creation of the problem in this session

KProblem problem(session,"B-5 Paint production");

// variables creation

char name[80];

int j,i;

for (j=0;j<NJ;j++) {

sprintf(name,"succ(%i)",j);

succ += (* new KIntVar( problem,name,0,NJ-1) );

succ[j].remVal(j);

sprintf(name,"y(%i)",j);

y += (* new KIntVar( problem,name,0,NJ-1) );

}

// initialization of CB array

for (j=0;j<NJ;j++) {

CB += 0;

}

// Cleaning time after every batch

for (j=0;j<NJ;j++) {

sprintf(name,"clean(%i)",j);

clean += (* new KIntVar( problem,name,0,1000) );

for (i=0;i<NJ;i++) {

CB[i] = CLEAN[j][i];

}

KEltTerm kelt(CB,succ[j]);

problem.post(new KElement(kelt,clean[j],"element"));

}

// objective variable creation

cycleTime = new KIntVar(problem,"cycleTime",0,1000);

// Objective: minimize the duration of a production cycle

KLinTerm cycleTerm;

for (j=0;j<NJ;j++) {

cycleTerm = cycleTerm + clean[j] + DUR[j];

}

problem.post(cycleTerm == *cycleTime);

// One successor and one predecessor per batch

problem.post(new KAllDifferent("alldiff",succ));

// Exclude subtours

for (i=0;i<NJ;i++) {

for (j=1;j<NJ;j++) {

if (i!=j) {

problem.post(new KGuard( succ[i] == j , y[j] == y[i] + 1 ); }

}

}

// propagating problem

if (problem.propagate()) {

printf("Problem is infeasible\n");

exit(1);

}

// Solve the problem

// creation of the solver

KSolver solver(problem);

// setting objective and sense of optimization

problem.setSense(KProblem::Minimize);

problem.setObjective(*cycleTime);

int result = solver.optimize();

// solution printing

KSolution * sol = &problem.getSolution();

// print solution resume

sol->printResume();

// Solution printing

printf("Minimum cycle time: %i\n", sol->getValue(*cycleTime));

printf("Sequence of batches:\nBatch Duration Cleaning\n");

int first=0;

do {

printf("%i\t%i\t%i\n", first, DUR[first],sol->getValue(clean[first]));

first = sol->getValue(succ[first]);

} while (first!=0);

from kalis import *

### Data

# Number of paint batches (=jobs)

nb_jobs = 5

# Durations of jobs

jobs_durations = [40, 35, 45, 32, 50]

# Cleaning times between jobs

jobs_cleaning_times = [[0, 11, 7, 13, 11],

[5, 0, 13, 15, 15],

[13, 15, 0, 23, 11],

[9, 13, 5, 0, 3],

[3, 7, 7, 7, 0]]

max_cleaning_time = max(max(jobs_cleaning_times[j]) for j in range(nb_jobs))

### Creation of the problem

# Creation of the Kalis session

session = KSession()

# Creation of the optimization problem

problem = KProblem(session, "B-5 Paint production")

### Variables creation

# Successor of a batch

batch_successor = KIntVarArray()

for j in range(nb_jobs):

batch_successor += KIntVar(problem, "succ(%d)" % j, 0, nb_jobs - 1)

batch_successor[j].remVal(j)

# Cleaning times after a batch

batch_cleaning_time = KIntVarArray()

for j in range(nb_jobs):

batch_cleaning_time += KIntVar(problem, "clean(%d)" % j, 0, max_cleaning_time)

# Variables for excluding subtours

job_position_in_cycle = KIntVarArray() # i.e. y_j variables

for j in range(nb_jobs):

job_position_in_cycle += KIntVar(problem, "y(%d)" % j, 0, nb_jobs - 1)

### Constraints creation

# Cleaning time after every batch:

# i.e. "batch_cleaning_time[j] == jobs_cleaning_times[batch_succesor[j]]"

for j in range(nb_jobs):

K_cleaning_time = KIntArray() # convert Python list to KIntArray

for i in range(nb_jobs):

res = K_cleaning_time.add(jobs_cleaning_times[j][i])

kelt = KEltTerm(K_cleaning_time, batch_successor[j])

problem.post(kelt == batch_cleaning_time[j])

# One successor and on predecessor per batch

problem.post(KAllDifferent("alldiff", batch_successor))

# Exclude subtours

for i in range(nb_jobs):

for j in range(1, nb_jobs):

if i != j:

problem.post( KGuard(batch_successor[i] == j,

job_position_in_cycle[j] == (job_position_in_cycle[i] + 1)))

# Set objective

cycle_time = KIntVar(problem, "cycle_time", 0, 1000)

batch_cleaning_times_sum = 0

for j in range(nb_jobs):

batch_cleaning_times_sum += batch_cleaning_time[j]

problem.post(cycle_time == (batch_cleaning_times_sum + sum(jobs_durations)))

# First propagation to check inconsistency

if problem.propagate():

print("Problem is infeasible")

sys.exit(1)

### Solve the problem

# Set the solver

solver = KSolver(problem)

# Setting objective and sense of optimization

problem.setSense(KProblem.Minimize)

problem.setObjective(cycle_time)

# Run optimization

result = solver.optimize()

# Solution printing

if result:

solution = problem.getSolution()

solution.printResume()

print("Minimum cycle time: %d" % solution.getValue(cycle_time))

print("Sequence of batches:")

print("Batch Duration Cleaning")

j = solution.getValue(batch_successor[0])

while j != 0:

print("%d\t%d\t%d" % (j, jobs_durations[j],

solution.getValue(batch_cleaning_time[j])))

j = solution.getValue(batch_successor[j])

// Number of paint batches (=jobs)

int NJ = 5;

// Durations of jobs

int[] DUR = {40, 35, 45 ,32 ,50};

// Cleaning times between jobs

int[][] CLEAN = {

{ 0, 11, 7, 13, 11 },

{ 5, 0, 13, 15, 15 },

{ 13, 15, 0, 23, 11 },

{ 9, 13, 5, 0, 3 },

{ 3, 7, 7, 7, 0 } };

// Cleaning times after a batch

KIntArray CB = new KIntArray();

// Successor of a batch

KIntVarArray succ = new KIntVarArray();

// Cleaning time after batches

KIntVarArray clean = new KIntVarArray();

// Variables for excluding subtours

KIntVarArray y = new KIntVarArray();

// Objective variable

KIntVar cycleTime = new KIntVar();

// Creation of the problem in this session

KProblem problem = new KProblem(session,"B-5 Paint production");

// variables creation

int j,i;

for (j=0;j<NJ;j++)

{

succ.add(new KIntVar(problem,"succ(" + j + ")",0,NJ-1));

succ.getElt(j).remVal(j);

y.add(new KIntVar(problem,"y(" + j + ")",0,NJ-1));

}

// Cleaning time after every batch

for (j=0;j<NJ;j++)

{

clean.add(new KIntVar(problem,"clean(" + j + ")",0,1000) );

for (i=0;i<NJ;i++)

{

CB.add(CLEAN[j][i]);

}

KEltTerm kelt = new KEltTerm(CB,succ.getElt(j));

problem.post(new KElement(kelt,clean.getElt(j),"element"));

}

// objective variable creation

cycleTime = new KIntVar(problem,"cycleTime",0,1000);

// Objective: minimize the duration of a production cycle

KLinTerm cycleTerm = new KLinTerm();

int sumOfDUR = 0;

for (j=0;j<NJ;j++)

{

cycleTerm.add(clean.getElt(j),1);

sumOfDUR += DUR[j];

}

KNumVarArray intVarArrayToSet = cycleTerm.getLvars();

KDoubleArray coeffsToSet = cycleTerm.getCoeffs();

intVarArrayToSet.add(cycleTime);

coeffsToSet.add(-1);

problem.post(new KNumLinComb("",coeffsToSet,intVarArrayToSet,-sumOfDUR,KNumLinComb.LinCombOperator.Equal));

// One successor and one predecessor per batch

problem.post(new KAllDifferent("alldiff",succ));

// Exclude subtours

for (i=0;i<NJ;i++)

{

for (j=1;j<NJ;j++)

{

if (i!=j)

{

problem.post(new KGuard( new KEqualXc(succ.getElt(i),j) , new KGreaterOrEqualXyc(y.getElt(j),y.getElt(i), 1)));

}

}

}

// propagating problem

if (problem.propagate())

{

System.out.println("Problem is infeasible");

exit(1);

}

// Solve the problem

// creation of the solver

KSolver solver = new KSolver(problem);

// setting objective and sense of optimization

problem.setSense(KProblem.Sense.Minimize);

problem.setObjective(cycleTime);

int result = solver.optimize();

// solution printing

KSolution sol = problem.getSolution();

// print solution resume

sol.printResume();

// Solution printing

System.out.println("Minimum cycle time: " + sol.getValue(cycleTime));

System.out.println("Sequence of batches:");

System.out.println("Batch Duration Cleaning:");

int first=0;

do {

System.out.print(first + "\t" + DUR[first] + "\t" + sol.getValue(clean.getElt(first)) + "\n");

first = sol.getValue(succ.getElt(first));

} while (first!=0);

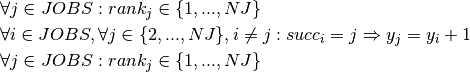

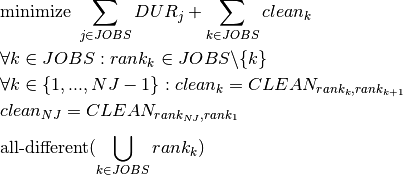

Formulation of model 2¶

We may choose to implement the paint production problem using rank variables similarly to the sequencing model in section 11.3. As before, let  be the set of batches to produce,

be the set of batches to produce,  the processing time for batch

the processing time for batch  , and

, and  the cleaning time between the consecutive batches

the cleaning time between the consecutive batches  and

and  . We introduce decision variables

. We introduce decision variables  taking their values in

taking their values in  , for the number of the job in position

, for the number of the job in position  . Variables

. Variables  with

with  now denote the duration of the

now denote the duration of the  cleaning time. This duration is obtained by indexing

cleaning time. This duration is obtained by indexing  with the values of two consecutive

with the values of two consecutive  variables. We thus have the following problem formulation.

variables. We thus have the following problem formulation.

As in model 1, the objective function sums up the processing and cleaning times of all batches. Although not strictly necessary from the mathematical point of view, we use different sum indices for durations and cleaning times to show the difference between summing over jobs or job positions. We now have an all-different constraint over the rank variables to guarantee that every batch occurs exactly once in the production sequence.

Implementation of model 2¶

The implementation of the second model uses the 2-dimensional version of the KElement constraint in Artelys Kalis.

// Number of paint batches (=jobs)

int NJ = 5;

// Durations of jobs

int DUR[] = {40, 35, 45 ,32 ,50};

// Cleaning times between jobs

KIntMatrix CLEAN(5,5,0,"CLEAN");

CLEAN[0][0] = 0;CLEAN[1][0] = 11;CLEAN[2][0] = 7;CLEAN[3][0] = 13;CLEAN[4][0] = 11;

CLEAN[0][1] = 5;CLEAN[1][1] = 0;CLEAN[2][1] = 13;CLEAN[3][1] = 15;CLEAN[4][1] = 15;

CLEAN[0][2] = 13;CLEAN[1][2] = 15;CLEAN[2][2] = 0;CLEAN[3][2] = 23;CLEAN[4][2] = 11;

CLEAN[0][3] = 9;CLEAN[1][3] = 13;CLEAN[2][3] = 5;CLEAN[3][3] = 0;CLEAN[4][3] = 3;

CLEAN[0][4] = 3;CLEAN[1][4] = 7;CLEAN[2][4] = 7;CLEAN[3][4] = 7;CLEAN[4][4] = 0;

// Successor of a batch

KIntVarArray rank;

// Cleaning time after batches

KIntVarArray clean;

// Objective variable

KIntVar * cycleTime;

// Creation of the problem in this session

KProblem problem(session,"B-5 Paint production");

// variables creation

char name[80];

int k,j,i;

for (j=0;j<NJ;j++) {

sprintf(name,"rank(%i)",j);

rank += (* new KIntVar( problem,name,0,NJ-1) );

sprintf(name,"clean(%i)",j);

clean += (* new KIntVar( problem,name,0,1000) );

}

// Cleaning time after every batch

for (k=0;k<NJ;k++) {

if (k < NJ-1) {

KEltTerm2D kelt(CLEAN,rank[k],rank[k+1]);

problem.post(new KElement2D(kelt,clean[k],"element"));

} else {

KEltTerm2D kelt(CLEAN,rank[k],rank[0]);

problem.post(new KElement2D(kelt,clean[k],"element"));

}

}

// objective variable creation

cycleTime = new KIntVar(problem,"cycleTime",0,1000);

// Objective: minimize the duration of a production cycle

KLinTerm cycleTerm;

for (j=0;j<NJ;j++) {

cycleTerm = cycleTerm + DUR[j];

}

KLinTerm cleanTerm;

for (k=0;k<NJ;k++) {

cleanTerm = cleanTerm + clean[k];

}

problem.post(cycleTerm + cleanTerm == *cycleTime);

// One position for every job

problem.post(new KAllDifferent("alldiff",rank));

// propagating problem

if (problem.propagate()) {

printf("Problem is infeasible\n");

exit(1);

}

// Solve the problem

// creation of the solver

KSolver solver(problem);

// setting objective and sense of optimization

problem.setSense(KProblem::Minimize);

problem.setObjective(*cycleTime);

int result = solver.optimize();

// solution printing

KSolution * sol = &problem.getSolution();

// print solution resume

sol->printResume();

// Solution printing

printf("Minimum cycle time: %i\n", sol->getValue(*cycleTime));

printf("Sequence of batches:\nBatch Duration Cleaning\n");

for (k=0;k<NJ;k++) {

printf("%i\t%i\t%i\n", sol->getValue(rank[k]), DUR[sol->getValue(rank[k])], sol->getValue(clean[k]));

}

### Data

# Number of paint batches (=jobs)

nb_jobs = 5

# Durations of jobs

jobs_durations = [40, 35, 45, 32, 50]

# Cleaning times between jobs

jobs_cleaning_times = [[0, 11, 7, 13, 11],

[5, 0, 13, 15, 15],

[13, 15, 0, 23, 11],

[9, 13, 5, 0, 3],

[3, 7, 7, 7, 0]]

max_cleaning_time = max(max(jobs_cleaning_times[j]) for j in range(nb_jobs))

# Setting data as a KIntMatrix

K_cleaning_times_matrix = KIntMatrix(5, 5, 0, "CLEAN")

for i in range(nb_jobs):

for j in range(nb_jobs):

K_cleaning_times_matrix.setMatrix(i, j, jobs_cleaning_times[i][j])

### Creation of the problem

# Creation of the Kalis session

session = KSession()

# Creation of the problem in this session

problem = KProblem(session, "B-5 Paint production")

### Variable creation

# Successor of a batch

batch_rank = KIntVarArray()

for j in range(nb_jobs):

batch_rank += KIntVar(problem, "rank(%d)" % j, 0, nb_jobs - 1)

# Cleaning time after batches

batch_cleaning_time = KIntVarArray()

for j in range(nb_jobs):

batch_cleaning_time += KIntVar(problem, "clean(%d)" % j, 0, max_cleaning_time)

### Constraints creation

# Set cleaning times after every batch

for k in range(nb_jobs):

if k < nb_jobs - 1:

kelt = KEltTerm2D(K_cleaning_times_matrix, batch_rank[k], batch_rank[k + 1])

problem.post(KElement2D(kelt, batch_cleaning_time[k], "element"))

else:

kelt = KEltTerm2D(K_cleaning_times_matrix, batch_rank[k], batch_rank[0])

problem.post(KElement2D(kelt, batch_cleaning_time[k], "element"))

# One position for every job

problem.post(KAllDifferent("alldiff", batch_rank))

# Set objective

cycle_time = KIntVar(problem, "cycle_time", 0, 1000)

batch_cleaning_times_sum = 0

for j in range(nb_jobs):

batch_cleaning_times_sum += batch_cleaning_time[j]

problem.post(cycle_time == (batch_cleaning_times_sum + sum(jobs_durations)))

# First propagation to check inconsistency

if problem.propagate():

print("Problem is infeasible")

sys.exit(1)

### Solve the problem

# Set the solver

solver = KSolver(problem)

# Setting objective and sense of optimization

problem.setSense(KProblem.Minimize)

problem.setObjective(cycle_time)

# Run optimization

result = solver.optimize()

# Solution printing

if result:

solution = problem.getSolution()

solution.printResume()

print("Minimum cycle time: %d" % solution.getValue(cycle_time))

print("Sequence of batches:")

print("Batch Duration Cleaning")

for k in range(nb_jobs):

job_id = solution.getValue(batch_rank[k])

print("%d\t%d\t%d" % (job_id, jobs_durations[job_id],

solution.getValue(batch_cleaning_time[k])))

// Cleaning times between jobs

KIntMatrix CLEAN = new KIntMatrix(5, 5, 0, "CLEAN");

CLEAN.setMatrix(0, 0, 0);

CLEAN.setMatrix(1,0,11);

CLEAN.setMatrix(2,0,7);

CLEAN.setMatrix(3,0,13);

CLEAN.setMatrix(4,0,11);

CLEAN.setMatrix(0,1,5);

CLEAN.setMatrix(1,1,0);

CLEAN.setMatrix(2,1,13);

CLEAN.setMatrix(3,1,15);

CLEAN.setMatrix(4,1,15);

CLEAN.setMatrix(0,2,13);

CLEAN.setMatrix(1,2,15);

CLEAN.setMatrix(2,2,0);

CLEAN.setMatrix(3,2,23);

CLEAN.setMatrix(4,2,11);

CLEAN.setMatrix(0,3,9);

CLEAN.setMatrix(1,3,13);

CLEAN.setMatrix(2,3,5);

CLEAN.setMatrix(3,3,0);

CLEAN.setMatrix(4,3,3);

CLEAN.setMatrix(0,4,3);

CLEAN.setMatrix(1,4,7);

CLEAN.setMatrix(2,4,7);

CLEAN.setMatrix(3,4,7);

CLEAN.setMatrix(4,4,0);

// Successor of a batch

KIntVarArray rank = new KIntVarArray();

// Cleaning time after batches

KIntVarArray clean = new KIntVarArray();

// Objective variable

KIntVar cycleTime = new KIntVar();

// Creation of the problem in this session

KProblem problem = new KProblem(session, "B-5 Paint production");

// variables creation

int k,j;

for (j=0; j<NJ; j++)

{

rank.add(new KIntVar(problem, "rank(" + j + ")", 0, NJ-1) );

clean.add(new KIntVar(problem, "clean(" + j + ")", 0, 1000) );

}

// Cleaning time after every batch

for (k=0; k<NJ; k++)

{

if (k < NJ-1)

{

KEltTerm2D kelt = new KEltTerm2D(CLEAN, rank.getElt(k), rank.getElt(k+1));

problem.post(new KElement2D(kelt, clean.getElt(k), "element"));

} else {

KEltTerm2D kelt = new KEltTerm2D(CLEAN, rank.getElt(k), rank.getElt(0));

problem.post(new KElement2D(kelt, clean.getElt(k), "element"));

}

}

// objective variable creation

cycleTime = new KIntVar(problem, "cycleTime", 0, 1000);

// Objective: minimize the duration of a production cycle

KLinTerm cleanTerm = new KLinTerm();

int sumOfDUR = 0;

for (j=0; j<NJ; j++)

{

cleanTerm.add(clean.getElt(j),1);

sumOfDUR += DUR[j];

}

KNumVarArray intVarArrayToSet = cleanTerm.getLvars();

KDoubleArray coeffsToSet = cleanTerm.getCoeffs();

intVarArrayToSet.add(cycleTime);

coeffsToSet.add(-1);

problem.post(new KNumLinComb("",coeffsToSet,intVarArrayToSet,sumOfDUR,KNumLinComb.LinCombOperator.Equal));

// One position for every job

problem.post(new KAllDifferent("alldiff",rank));

// propagating problem

if (problem.propagate())

{

System.out.println("Problem is infeasible");

exit(1);

}

// Solve the problem

// creation of the solver

KSolver solver = new KSolver(problem);

// setting objective and sense of optimization

problem.setSense(KProblem.Sense.Minimize);

problem.setObjective(cycleTime);

solver.optimize();

// solution printing

KSolution sol = problem.getSolution();

// print solution resume

sol.printResume();

// Solution printing

System.out.println("Minimum cycle time: " + sol.getValue(cycleTime));

System.out.print("Sequence of batches:\nBatch Duration Cleaning\n");

for (k=0; k<NJ; k++)

{

System.out.print(sol.getValue(rank.getElt(k)) + "\t" + DUR[sol.getValue(rank.getElt(k))] + "\t" + sol.getValue(clean.getElt(k)) + "\n");

}

Results¶

The minimum cycle time for this problem is 243 minutes which is achieved with the following sequence of batches: 1  2

2  5

5  3

3  4

4  1. This time includes 202 minutes of (incompressible) processing time and 41 minutes of cleaning.

1. This time includes 202 minutes of (incompressible) processing time and 41 minutes of cleaning.