Paint production 2¶

In this section we work once more with the paint production problem. The objective of this problem is to determine a production cycle of minimal length for a given set of jobs with sequence-dependent cleaning times between every pair of jobs.

Model formulation¶

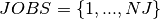

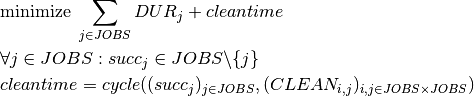

The problem formulation in section 11.5 uses KAllDifferent constraints to ensure that every job occurs once only, calculates the duration of cleaning times with KElement constraints, and introduces auxiliary variables and constraints to prevent subcycles in the production sequence. All these constraints can be expressed by a single constraint relation, the KCycle constraint. Let  be the set of batches to produce,

be the set of batches to produce,  the processing time for batch

the processing time for batch  , and

, and  the cleaning time between the consecutive batches

the cleaning time between the consecutive batches  and

and  . As before we define decision variables

. As before we define decision variables  taking their values in

taking their values in  , to indicate the successor of every job. The complete model formulation is the following,

, to indicate the successor of every job. The complete model formulation is the following,

where cycle stands for the relation sequence into a single cycle without subcycles or repetitions. The variable cleantime equals the total duration of the cycle.

Implementation¶

The model using the KCycle constraint looks as follows.

// Number of paint batches (=jobs)

int NJ = 5;

// Durations of jobs

int DUR[] = {40, 35, 45 ,32 ,50};

// Cleaning times between jobs

KIntMatrix CLEAN(5,5,0,"CLEAN");

CLEAN[0][0] = 0;CLEAN[1][0] = 11;CLEAN[2][0] = 7;CLEAN[3][0] = 13;CLEAN[4][0] = 11;

CLEAN[0][1] = 5;CLEAN[1][1] = 0;CLEAN[2][1] = 13;CLEAN[3][1] = 15;CLEAN[4][1] = 15;

CLEAN[0][2] = 13;CLEAN[1][2] = 15;CLEAN[2][2] = 0;CLEAN[3][2] = 23;CLEAN[4][2] = 11;

CLEAN[0][3] = 9;CLEAN[1][3] = 13;CLEAN[2][3] = 5;CLEAN[3][3] = 0;CLEAN[4][3] = 3;

CLEAN[0][4] = 3;CLEAN[1][4] = 7;CLEAN[2][4] = 7;CLEAN[3][4] = 7;CLEAN[4][4] = 0;

// Cleaning times after a batch

KIntArray CB;

// Successor of a batch

KIntVarArray succ;

// Objective variable

KIntVar * cycleTime;

// Objective variable

KIntVar * cleanTime;

// Creation of the problem in this session

KProblem problem(session,"B-5 Paint production");

// variables creation

char name[80];

int j,i;

for (j=0;j<NJ;j++) {

sprintf(name,"succ(%i)",j);

succ += (* new KIntVar( problem,name,0,NJ-1) );

succ[j].remVal(j);

}

cleanTime = new KIntVar(problem,"cleanTime",0,1000);

// Assign values to 'succ' variables as to obtain a single cycle

// 'cleanTime' is the sum of the cleaning times

problem.post(new KCycle(&succ, NULL,cleanTime, &CLEAN) );

// objective variable creation

cycleTime = new KIntVar(problem,"cycleTime",0,1000);

// Objective: minimize the duration of a production cycle

KLinTerm cycleTerm;

for (j=0;j<NJ;j++) {

cycleTerm = cycleTerm + DUR[j];

}

problem.post(cycleTerm + *cleanTime == *cycleTime);

// propagating problem

if (problem.propagate()) {

printf("Problem is infeasible\n");

exit(1);

}

// Solve the problem

// creation of the solver

KSolver solver(problem);

// setting objective and sense of optimization

problem.setSense(KProblem::Minimize);

problem.setObjective(*cycleTime);

int result = solver.optimize();

// solution printing

KSolution * sol = &problem.getSolution();

// print solution resume

sol->printResume();

// Solution printing

printf("Minimum cycle time: %i\n", sol->getValue(*cycleTime));

printf("Sequence of batches:\nBatch Duration Cleaning\n");

int first=0;

do {

printf("%i\t%i\t%i\n", first, DUR[first],CLEAN[first][sol->getValue(succ[first])]);

first = sol->getValue(succ[first]);

} while (first!=0);

from kalis import *

### Data

# Number of paint batches (=jobs)

nb_jobs = 5

# Durations of jobs

jobs_durations = [40, 35, 45, 32, 50]

# Cleaning times between jobs

jobs_cleaning_times = [[0, 11, 7, 13, 11],

[5, 0, 13, 15, 15],

[13, 15, 0, 23, 11],

[9, 13, 5, 0, 3],

[3, 7, 7, 7, 0]]

### Creation of the problem

# Creation of the Kalis session

session = KSession()

# Creation of the problem in this session

problem = KProblem(session, "B-5 Paint production")

# Setting data as a KIntMatrix

K_cleaning_times_matrix = KIntMatrix(5, 5, 0, "CLEAN")

for i in range(nb_jobs):

for j in range(nb_jobs):

K_cleaning_times_matrix.setMatrix(i, j, jobs_cleaning_times[i][j])

### Variables creation

# Successor of a batch

batch_successor = KIntVarArray()

for j in range(nb_jobs):

batch_successor += KIntVar(problem, "succ(%d)" % j, 0, nb_jobs - 1)

batch_successor[j].remVal(j)

# Cycle time monitoring

clean_time = KIntVar(problem, "cleanTime", 0, 1000)

# Assign values to 'batch_successor' variables as to obtain a single cycle

# 'clean_time' is the sum of the cleaning times

problem.post(KCycle(batch_successor, None, clean_time, K_cleaning_times_matrix))

# Objective variable

cycle_time = KIntVar(problem, "cycleTime", 0, 1000)

problem.post(sum(jobs_durations) + clean_time == cycle_time)

### Solve the problem

# First propagation to check inconsistency

if problem.propagate():

print("Problem is infeasible")

sys.exit(1)

# Set the solver

solver = KSolver(problem)

# Setting objective and sense of optimization

problem.setSense(KProblem.Minimize)

problem.setObjective(cycle_time)

# Run optimization

result = solver.optimize()

# Solution printing

if result:

solution = problem.getSolution()

solution.printResume()

print("Minimum cycle time: %d" % solution.getValue(cycle_time))

print("Sequence of batches:")

print("Batch Duration Cleaning")

j = solution.getValue(batch_successor[0])

while j != 0:

next_job = solution.getValue(batch_successor[j])

print("%d\t%d\t%d" % (j, jobs_durations[j], jobs_cleaning_times[j][next_job]))

j = next_job

// Cleaning times between jobs

KIntMatrix CLEAN = new KIntMatrix(5,5,0,"CLEAN");

CLEAN.setMatrix(0,0,0);

CLEAN.setMatrix(1,0,11);

CLEAN.setMatrix(2,0,7);

CLEAN.setMatrix(3,0,13);

CLEAN.setMatrix(4,0,11);

CLEAN.setMatrix(0,1,5);

CLEAN.setMatrix(1,1,0);

CLEAN.setMatrix(2,1,13);

CLEAN.setMatrix(3,1,15);

CLEAN.setMatrix(4,1,15);

CLEAN.setMatrix(0,2,13);

CLEAN.setMatrix(1,2,15);

CLEAN.setMatrix(2,2,0);

CLEAN.setMatrix(3,2,23);

CLEAN.setMatrix(4,2,11);

CLEAN.setMatrix(0,3,9);

CLEAN.setMatrix(1,3,13);

CLEAN.setMatrix(2,3,5);

CLEAN.setMatrix(3,3,0);

CLEAN.setMatrix(4,3,3);

CLEAN.setMatrix(0,4,3);

CLEAN.setMatrix(1,4,7);

CLEAN.setMatrix(2,4,7);

CLEAN.setMatrix(3,4,7);

CLEAN.setMatrix(4,4,0);

// Successor of a batch

KIntVarArray succ = new KIntVarArray();

// Objective variable

KIntVar cycleTime = new KIntVar();

// Objective variable

KIntVar cleanTime = new KIntVar();

// Creation of the problem in this session

KProblem problem = new KProblem(session,"B-5 Paint production");

// variables creation

int j;

for (j=0; j<NJ; j++)

{

succ.add(new KIntVar(problem, "succ(" + j + ")",0, NJ-1) );

succ.getElt(j).remVal(j);

}

cleanTime = new KIntVar(problem, "cleanTime", 0, 1000);

// Assign values to 'succ' variables as to obtain a single cycle

// 'cleanTime' is the sum of the cleaning times

problem.post(new KCycle(succ, null,cleanTime, CLEAN) );

// objective variable creation

cycleTime = new KIntVar(problem, "cycleTime", 0, 1000);

// Objective: minimize the duration of a production cycle

int sumOfDUR = 0;

for (j=0; j<NJ; j++)

{

sumOfDUR += DUR[j];

}

problem.post(new KGreaterOrEqualXyc(cycleTime, cleanTime, sumOfDUR));

// propagating problem

if (problem.propagate())

{

System.out.println("Problem is infeasible");

exit(1);

}

// Solve the problem

// creation of the solver

KSolver solver = new KSolver(problem);

// setting objective and sense of optimization

problem.setSense(KProblem.Sense.Minimize);

problem.setObjective(cycleTime);

solver.optimize();

// solution printing

KSolution sol = problem.getSolution();

// print solution resume

sol.printResume();

// Solution printing

System.out.println("Minimum cycle time: " + sol.getValue(cycleTime));

System.out.print("Sequence of batches:\nBatch Duration Cleaning\n");

int first=0;

do {

System.out.print(first + "\t" + DUR[first] + "\t" + intp_value(CLEAN.getMatrix(first,sol.getValue(succ.getElt(first)))) + "\n");

first = sol.getValue(succ.getElt(first));

} while (first!=0);

Results¶

The optimal solution to this problem has a minimum cycle time of 243 minutes, resulting from 202 minutes of (incompressible) processing time and 41 minutes of cleaning. The problem statistics produced by Artelys Kalis for a model run reveal that the cycle version of this model is the most efficient way of representing and solving the problem: it takes fewer nodes and a shorter execution time than the two previous versions of the model.